Measurement Range:0 to 100,000 RPM

Accuracy:+/- 0.1% of full scale

Operating Temperature:-40°C to +70°C (-40°F to +158°F)

Data Transmission Protocol:RS-485 Modbus RTU

Power Supply:12 to 24 VDC

Environmental Resistance:IP65 Dustproof and Splashproof

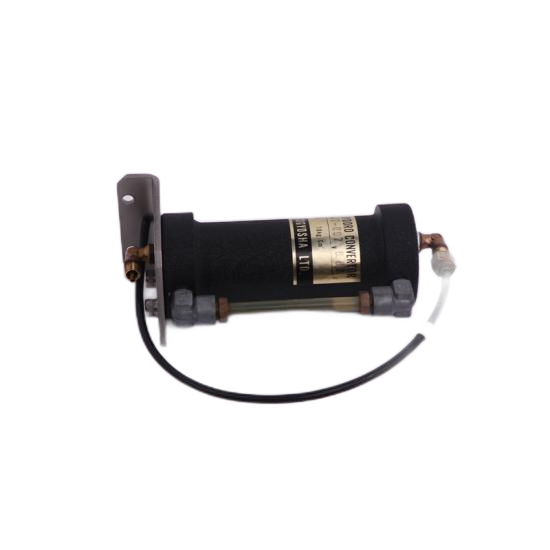

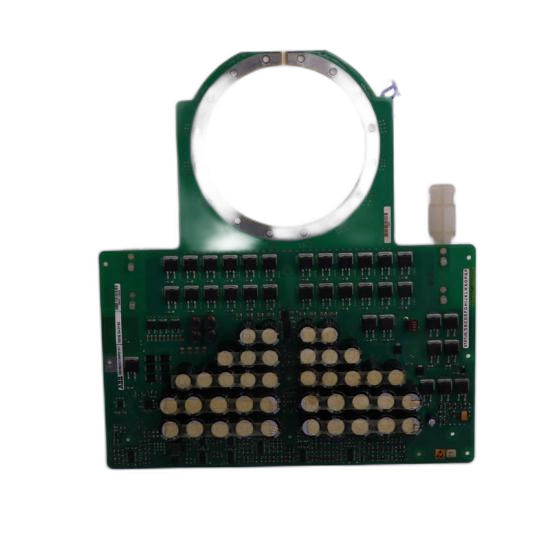

The GE Bently Nevada 135613-02 precision monitoring system is a cornerstone in industrial automation, offering a comprehensive suite of tools for real-time analysis and predictive maintenance. This system leverages advanced piezoelectric sensor technology to detect even the slightest vibrations in machinery, enabling early detection of wear and tear before it escalates into costly downtime.

Equipped with real-time signal processing capabilities, the 135613-02 provides detailed diagnostics on a wide range of parameters including speed, vibration, and temperature. Its high accuracy rating ensures that maintenance schedules are optimized, reducing unnecessary interventions and maximizing equipment lifespan.

Designed for robust performance across extreme environments, this monitoring system is suitable for use in temperatures ranging from -40°C to +85°C and can withstand humidity levels up to 95% without condensation. Its power consumption is optimized at 15W (Max), ensuring efficient energy usage without compromising on functionality.

Installation is straightforward, with modular design allowing for easy integration into existing systems. Comprehensive documentation and user-friendly interfaces make setup quick and intuitive, minimizing downtime during implementation. The system is compatible with a variety of control systems, ensuring seamless integration into diverse industrial settings.

Backed by GE‘s reputation for reliability and innovation, the GE Bently Nevada 135613-02 precision monitoring system is a strategic investment for industries seeking to enhance operational efficiency, reduce maintenance costs, and extend the longevity of their assets.

There are no reviews yet.